PROUDLY MADE IN THE USA

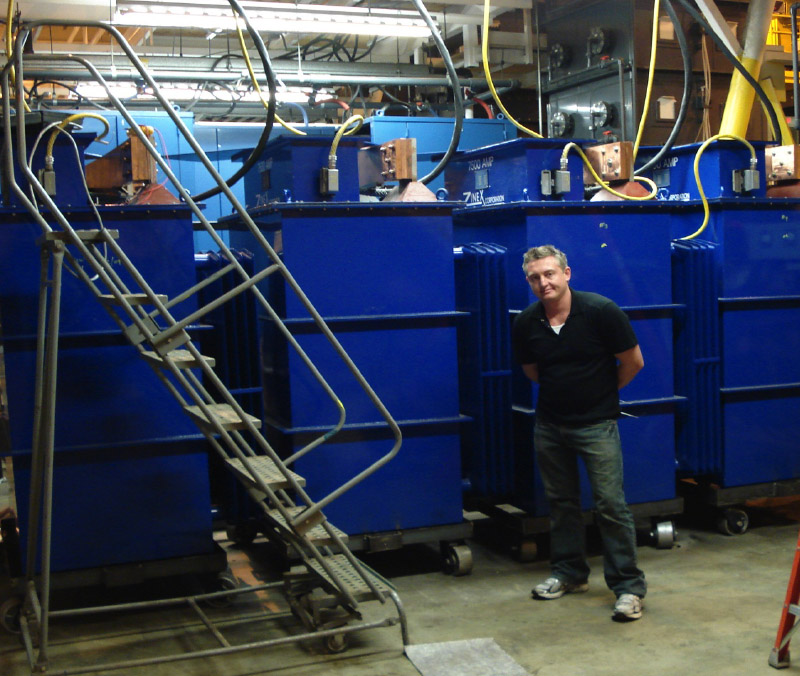

ZINEX Oil-Cooled Rectifiers

Zinex Corporation oil-cooled rectifiers are well suited for corrosive environments, ie. Marine & Offshore industries. This series is designed to run continuously at maximum duty cycle while still offering dependability under the most extreme conditions.

Built to meet IEEE/IECEx/ATEX North American Standards

Product Ranges included, but not limited to CLASS 1, Division 1 & 2, Groups A, B, C, D, Zone 1 & 2, GAS Groups IIC, IIB+H2, IIB, IIA.

Applications:

• Fuel Cell • Chlorination Units • Electrolytic Cells

• Water Treatment • Waste water Treatment

• Disinfection Systems • Water Reclamation

WHY USE ZINEX OIL COOLED RECTIFIERS

Zinex Corporation oil cooled rectifiers are designed for corrosive enviroments in the Plating Industry. This series is ideal for applications where continuous duty is required.

IMPROVEMENT OVER CONVENTIONAL WATER AND AIR COOLED RECTIFIERS

(50 through 30,000 Amp output)

- Low ripple

- Low Maintenance

- Low Maintenance Costs

- Longer life

- No Fans = No Noise

- No water hook-ups

- Smaller than conventional air and water cooled units

- Suitable for indoor and outdoor use

- Better value for your money

Operating Environment

- Designed to run in all types of environments

- (All opening covers are fitted with rubber gaskets to prevent dust and moisture from getting into the unit)

- Example: High humidity, hot desert conditions, sea level, high altitude, corrosive environments, sub zero conditions

Professional Standards

- Built to meet Class 1, Division 1 or ATEX Zone 1

- UL, NEMA, IEEE, ANSI, ATEX Zone 1, and NEC Class 1 Division 1

- Can build to your specifications

Low Maintenance

- Change oil after 10-20 years in production

- No corrosion on internal devices

- Low failure rate on internal devices due to oil

- No moving parts

No Noise

- No fans

- Hermetically sealed inside steel

- Does not add to OSHA noise issues

Efficiency vs. Air/Water

- No lost power running fans or pumps

- Transformer steel is of the highest grade M4 material and all windings are splice free copper

- Solid state throughout, no moving parts

Continuous Operation

- Designed to run continuously at maximum duty cycle, while still offering dependability under the most severe conditions.

Custom Physical Dimensions

- Can build rectifier tanks to custom dimensions

- Tanks made out of steel, stainless steel, and aluminum

- Can powder coat or paint to customer spec

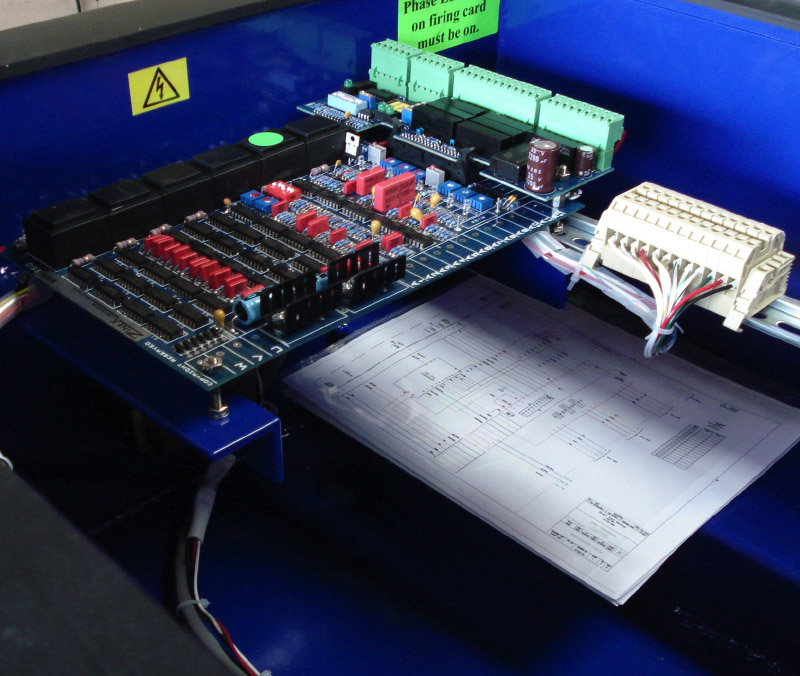

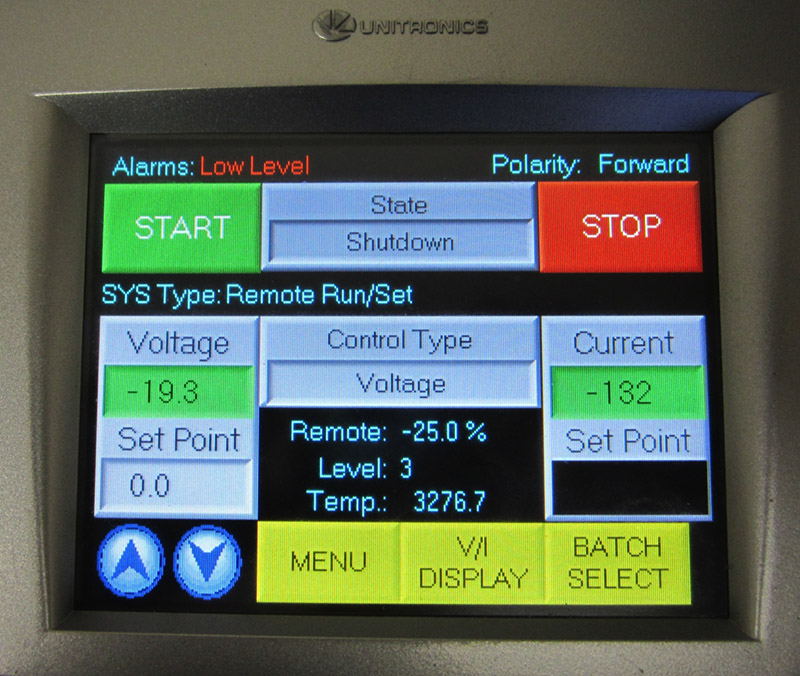

State-of-the-art Technology

Additional Features

- Remote Box

- Trip Alarm

- Oil Gage

- Over Current Alarm

- Over Temperature

- Short Circuit Protection

- Oil Level Display

- Low-Harmonics